In challenging industrial environments, workers face daily exposure to rough materials, harsh chemicals, and physically demanding tasks. Choosing the right personal protective equipment is essential, and among the most trusted tools on any job site is a pair of nitrile gloves. Known for their strength and resistance to wear, nitrile gloves offer superior protection compared to other disposable glove types.

This article explores the factors that make nitrile gloves durable, where they are used most effectively, and how to choose the right glove for your industrial setting.

Why Durability Matters in Heavy-Duty Nitrile Gloves

Durability is more than just how long a glove lasts. It determines how well the glove protects workers from injuries and exposure to harmful substances. In industries like automotive repair, construction, chemical processing, and equipment maintenance, gloves are exposed to extreme conditions. A weak glove can rip or puncture at the wrong moment, leading to contamination or injury.

Key reasons industrial durability is essential:

-

Constant exposure to oils, greases, solvents, and chemicals

-

Contact with sharp or abrasive surfaces and tools

-

Prolonged wear for long shifts or repetitive tasks

-

Protection from punctures caused by metal parts or debris

Nitrile gloves are manufactured to resist these conditions. They offer protection and performance that outperform traditional latex or vinyl gloves in tough workspaces.

What Makes Nitrile Gloves So Durable?

Nitrile is a synthetic rubber that offers several advantages over natural rubber latex. It is more resistant to chemicals and physical damage and does not cause allergic reactions in most users.

Features that make nitrile gloves more durable:

-

Up to three times more puncture-resistant than latex

-

High resistance to oils, solvents, and common industrial chemicals

-

Tear-resistant even under high tension or when stretched

-

Thick construction options with reinforced fingertips and palms

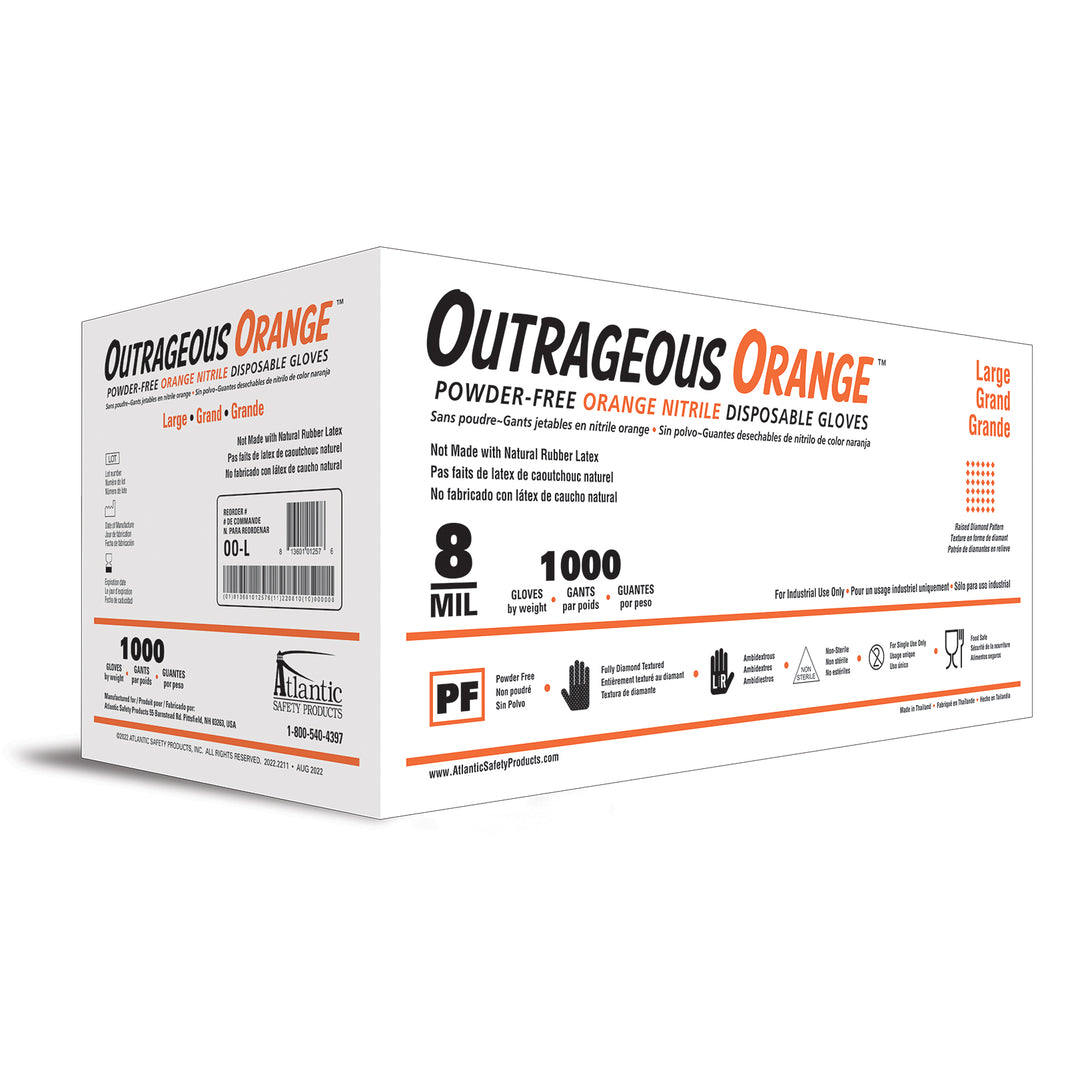

Some nitrile gloves are engineered with added grip textures, such as diamond or raised patterns, which enhance control during wet or oily tasks.

Environmental Factors That Impact Glove Longevity

Even the strongest glove can degrade if stored or used in poor conditions. Temperature, humidity, and sunlight all play a role in how long a glove remains effective.

-

Heat and UV Exposure: Nitrile gloves should be stored in a cool, dry place. Prolonged exposure to sunlight or heat can weaken the material, causing brittleness and reduced tensile strength.

-

Moisture and Humidity: Storing gloves in humid environments may promote surface degradation or contamination, especially if boxes are not sealed properly.

-

Chemical Storage Proximity: Avoid storing gloves near volatile chemicals or solvents, as fumes can leach into packaging and weaken the nitrile over time.

By properly storing gloves in controlled environments, companies can preserve glove integrity and reduce unnecessary waste.

Common Industrial Applications Where Nitrile Gloves Excel

Nitrile gloves are relied upon across a wide range of industrial settings. Their strength and chemical resistance make them ideal for jobs where protection and precision are both required.

Automotive and Mechanical Work

Technicians and mechanics frequently handle motor oil, brake fluid, and metal shavings. Nitrile gloves resist damage from solvents and provide a reliable barrier against grime and sharp edges.

Learn more about the features of our black nitrile gloves designed for automotive and industrial use.

Construction and Contracting

Contractors and construction crews work with abrasive surfaces like concrete, metal, and lumber. Nitrile gloves provide protection without sacrificing mobility, making them a smart choice for daily tasks.

Chemical Manufacturing

Handling industrial chemicals requires gloves that will not degrade or break down. Nitrile is highly resistant to a wide range of chemicals and is commonly used in manufacturing labs and facilities.

Industrial Cleaning and Maintenance

Cleaning crews need gloves that protect against disinfectants and degreasers while allowing them to grip tools and navigate confined spaces. Nitrile gloves with textured grips perform well in this role.

Understanding Glove Testing and Certification Standards

Durable nitrile gloves are tested using international standards to ensure they can withstand the demands of industrial work. When purchasing gloves, check for:

-

ASTM D6319: The standard for physical properties and quality in nitrile gloves

-

EN 374: Certification for chemical resistance and penetration protection

-

EN 388: Ratings related to abrasion, cut, tear, and puncture resistance (more common in reusable gloves, but relevant when assessing tough disposable options)

Reputable manufacturers use these standards to demonstrate their products meet minimum durability and safety benchmarks.

How Nitrile Compares to Other Glove Materials

When durability is your top priority, not all disposable gloves are equal. Here is a side-by-side comparison of common materials used in industrial gloves.

|

Glove Material |

Puncture Resistance |

Chemical Resistance |

Comfort |

Cost |

|

Nitrile |

Excellent |

Excellent |

Good |

Moderate |

|

Latex |

Fair |

Moderate |

Excellent |

Low |

|

Vinyl |

Poor |

Poor |

Fair |

Low |

|

Neoprene |

Good |

Good |

Good |

High |

Nitrile strikes a balance between strength, comfort, and affordability, making it the preferred option for most industrial applications.

How to Choose the Right Nitrile Glove for Your Worksite

Not all nitrile gloves are created equal. Choosing the right glove involves evaluating the task at hand and the hazards involved.

Consider the following features when choosing nitrile gloves:

Thickness: Gloves rated at 6 to 8 mils provide added protection for heavy-duty work while maintaining flexibility.

Grip Texture: Look for gloves with textured fingertips or palm grips to ensure better control during wet, greasy, or detailed work.

Extended Cuffs: Longer cuffs offer better protection for the wrists and lower arms in environments involving chemical exposure or splash risks.

Powder-Free Design: Powder-free gloves help reduce contamination and prevent irritation from airborne particles.

Why Atlantic Safety Products Heavy-Duty Nitrile Gloves Stand Out

Atlantic Safety Products builds their gloves to meet the rigorous demands of industrial professionals. Our gloves are tested for tensile strength, tear resistance, and chemical protection to ensure performance in the field.

Features that make our gloves ideal for harsh conditions:

-

Premium nitrile compound for added strength

-

Textured grip for improved handling

-

Available in multiple thickness levels and sizes

-

Latex-free and powder-free to reduce allergic reactions

-

Used by professionals in automotive, construction, and manufacturing sectors

Browse our full selection of industrial nitrile gloves built for demanding jobs.

Best Practices to Extend Glove Performance on the Job

Even the best nitrile gloves need to be used properly to ensure safety and performance. Here are some key practices to follow in industrial environments:

-

Store gloves in a dry, cool location away from sunlight or heat

-

Always check for signs of wear, including holes or weak seams, before using

-

Select the correct glove size to avoid tears or slipping

-

Never reuse disposable nitrile gloves

-

Use thicker gloves when working with sharp tools or strong chemicals

Following these practices helps reduce glove failure and keeps workers protected throughout their shift.

Final Thoughts

In harsh industrial settings, durable nitrile gloves are essential. Whether handling chemicals, operating tools, or performing repetitive tasks, nitrile offers the reliability, strength, and comfort that professionals need to work safely and effectively.

Choosing the right nitrile glove can reduce workplace injuries, increase efficiency, and lower long-term costs by minimizing waste and glove failure.