In high-stakes environments—like manufacturing, food processing, or healthcare—dexterity and safety are critical. Summer heat adds an extra challenge, making comfort just as important as protection. The right heavy-duty nitrile gloves can offer both. In this post, we’ll explore key factors to consider when choosing gloves for precision work in warm conditions, offer practical tips to maintain performance, and suggest products that address both dexterity and durability.

Why Heavy‑Duty Nitrile Gloves Matter in Summer

Balancing Strength and Sensitivity

Nitrile gloves are well-known for their puncture resistance and chemical protection. But heavy-duty nitrile gloves elevate these benefits further, offering thicker material that withstands rigorous use. However, with thickness comes the risk of reduced sensitivity. The ideal glove in summer needs to strike a fine balance: thick enough to protect, yet flexible enough for fine manipulation.

Temperature, Sweat, and Grip

Heat and humidity exacerbate hand sweating, leading to slippery gloves and reduced grip. Summer gloves should address moisture management—either through breathable materials, inner-talc or polymer coatings, or micro-texturing on the fingertips—thus helping technicians retain control over tools and delicate components.

Choosing the Right Heavy‑Duty Nitrile Gloves

1. Assessing Shell Thickness vs. Tactility

Evaluate the glove’s mil thickness. Heavy-duty gloves generally range between 6-8 mil (0.15–0.20 mm) or more. While thicker variants offer superior durability, they may impede the fine motor control needed in calibration, electronics assembly, or precision inspections.

Pro tip: Select gloves with graduated thickness—thicker along the palm and back, thinner at fingertips—to preserve dexterity.

2. Check for Micro-Texture and Anti‑Slip Features

In summer, a reliable grip is non-negotiable. Many heavy-duty nitrile gloves incorporate micro-textured fingertips or diamond-pattern designs that enhance friction, even in moist conditions. This ensures that tools and components remain securely in hand.

3. Choose Breathable and Cool Interfacing

A glove’s inner coating significantly impacts comfort. Polymer-dipped or talc-coated interiors reduce friction and ease donning and doffing, preventing excessive sweating. Some gloves use breathable nitrile blends that allow a degree of airflow while maintaining barrier protection.

4. Ensure High Abrasion and Chemical Resistance

During summer, working hours may increase. Heavy-duty nitrile gloves need to withstand long shifts, spill exposure, and abrasion. Look for gloves rated for abrasion resistance (e.g., ANSI/ISEA ABRASION LEVEL 4 or 5). If chemicals are involved, confirm compatibility—nitrile resists oils, solvents, and greases better than latex or vinyl.

5. Validate Comfort Without Sacrificing Size

Choosing the right size is just as critical as choosing the right type. A snug fit limits friction and blisters. Heavy-duty gloves with ergonomic designs reduce fatigue. Lightweight wrist cuffs and stretch-fit anatomies help maintain circulation during prolonged wear.

Summer-Specific Best Practices

-

Rotate Glove Styles: Keep both heavy-duty and lighter nitrile options on hand. Assign heavy-duty gloves for high-risk tasks and lighter models for detail work.

-

Implement Scheduled Glove Changes: Replace gloves at regular intervals—e.g., every 2–3 hours or when contaminated. This helps prevent sweat buildup and maintains dexterity.

-

Store Gloves in Cool, Dry Spaces: Avoid heat exposure before use. Gloves stored in cool areas stay supple and perform better during wear.

-

Use Moisture‑Wicking Hand Cleansers: Hand lotions or cleansing rubs with aloe or glycerin reduce sweat but dry quickly. Avoid greasy products that interfere with glove grip.

-

Educate on Proper Removal: In hot conditions, donning and doffing can be tricky. Train staff to peel gloves off correctly to avoid tearing and reduce contamination risk.

Recommended Heavy‑Duty Nitrile Gloves

At Atlantic Safety Products, we offer a curated selection of heavy-duty nitrile gloves designed with summer conditions in mind:

-

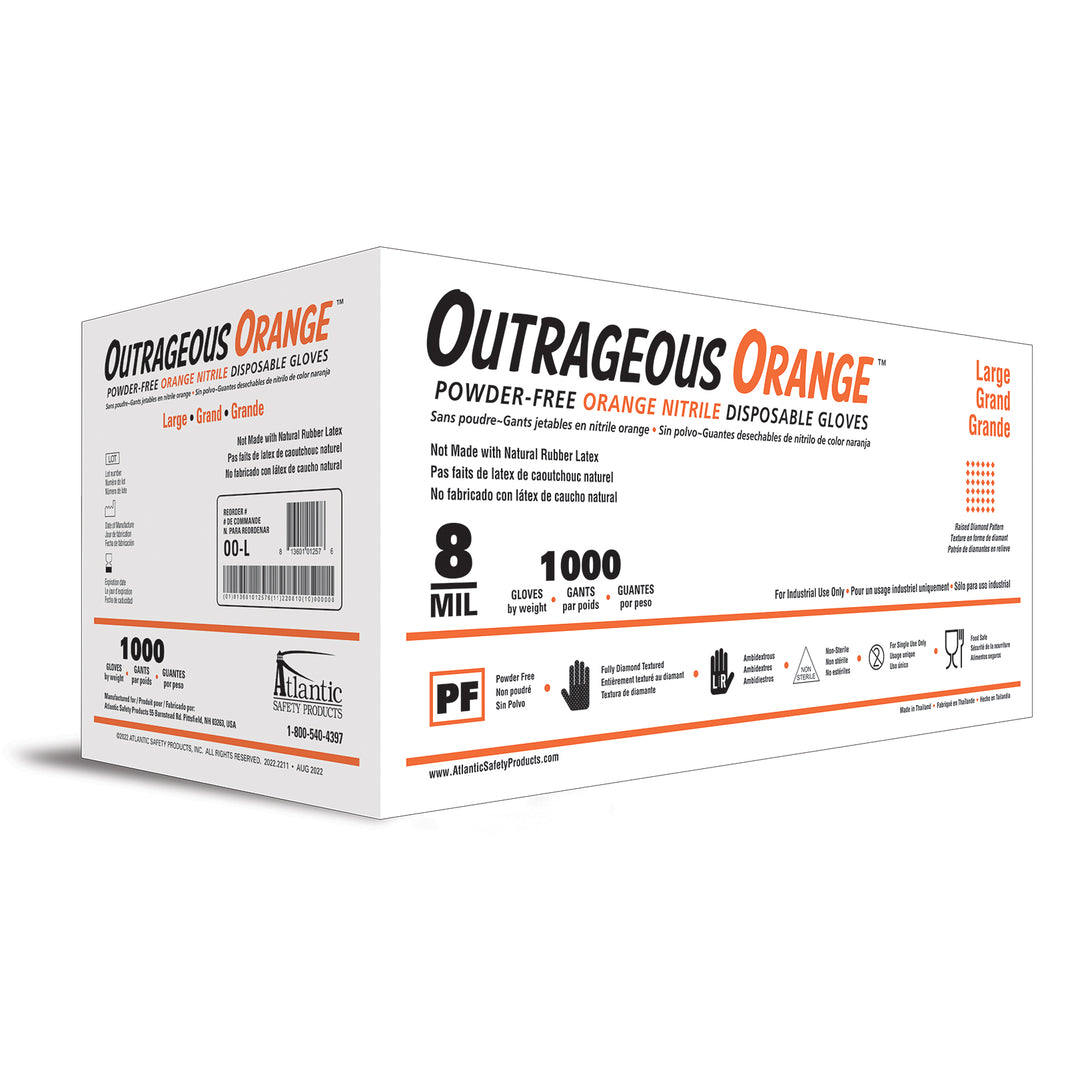

[Product A – Diamond‑Textured 8 Mil Nitrile Glove]

Designed with fingertips micro-etched for grip and a polymer liner for cool comfort. Ideal for food processing, automotive, and industrial settings. -

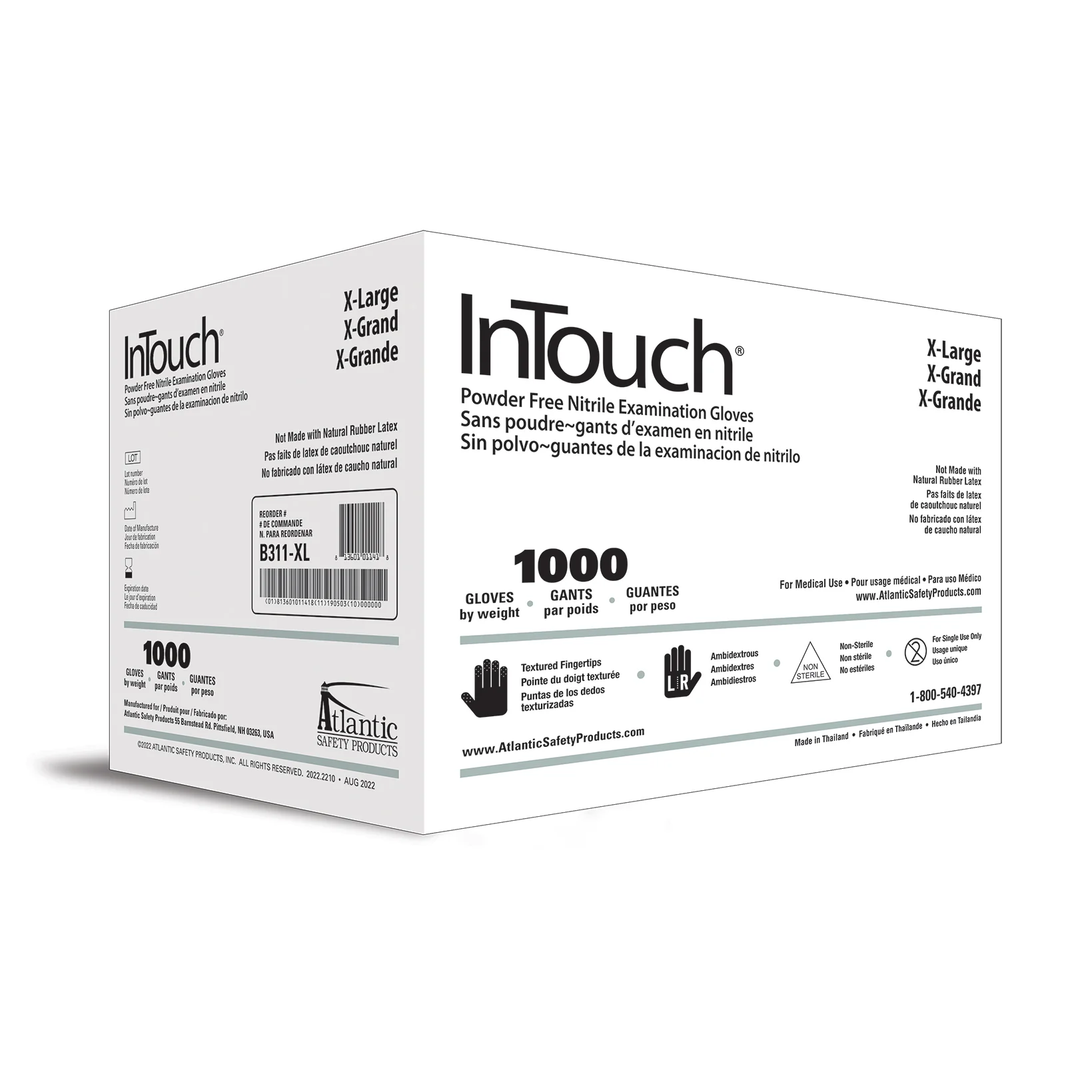

[Product B – Breathable 6 Mil Nitrile Exam Glove]

Lighter than our 8 mil option, but still ANSI Level 4 abrasion resistant. Excellent for lab work, electronics, or assembly tasks where sensitivity is a priority. -

[Product C – Powder‑Free 7 Mil Stretch Nitrile Inspection Glove]

A stretch-fit design allows better tactile response with enough thickness to support general maintenance and quality control applications.

For more information, visit our industrial glove guide or explore our chemical-resistant glove range to match specific ANSI/OSHA requirements.

Customizing for Your Summer Workflow

Task-Based Glove Selection

-

Fine Assembly & Electronics

Opt for the 6 mil breathable nitrile exam gloves—higher sensitivity, lower sweat retention. -

Heavy‑Duty Maintenance & Cleaning

Choose the 8 mil diamond‑textured glove—superior durability and wet grip. -

Inspection & Sampling

Use the stretch nitrile inspection glove—mix comfort with moderate protection.

Usage Guidelines by Role

|

Role / Task |

Suggested Glove Type |

Change Frequency |

|

Electronics assembly |

6 mil breathable nitrile exam glove |

Every 2–3 hrs or upon contamination |

|

Heavy‑duty maintenance/cleanup |

8 mil diamond‑textured glove |

As needed; end of shift minimum |

|

Quality control & sampling |

7 mil stretch nitrile inspection glove |

After each inspection cycle |

Why Our Gloves Stand Out in Summer

-

Advanced Cooling Features: All our heavy-duty nitrile gloves include polymer or talc inner coatings that reduce heat discomfort and friction during long periods of wear.

-

Performance-Driven Design: By combining durability with micro-textured surfaces, our gloves provide reliable protection without compromising precision.

-

Compliance Focused: We offer gloves certified to ANSI, FDA, and ISO standards, guiding customers to meet or surpass current industrial regulations.

Practical Tips for Maximum Impact

-

Keep a Dual-Stock System

Reserve both heavy‑duty and lightweight nitrile gloves in accessible stations to allow role-based switching. -

Monitor Usage Logs

Track glove change frequency and failure rates. If tearing occurs frequently, consider upsizing the mil thickness or switching to diamond-textured versions. -

Ensure Comprehensive Fit Range

With multiple glove styles, provide sizes XS–XL to accommodate all team members and reduce misuse. -

Refresh Hand Care Protocols

Encourage brief cooling and rehydration breaks to prevent heat stress. A simple hand lotion after removal helps reduce heat buildup in future use.

Final Thoughts

Selecting the right heavy duty nitrile gloves during the summer months isn’t just about protection—it’s about sustaining productivity, reducing errors, and ensuring team comfort. By evaluating thickness, texture, breathability, and fit, you can equip your workforce with gloves that feel like an extension of their hands, even under the sun’s pressure.

Whether your tasks involve microscopic assembly or heavy maintenance, Atlantic Safety Products has an optimized nitrile glove solution ready. Browse our industrial glove collection, evaluate specifications, and let us help you implement smart glove protocols that conquer heat and dexterity challenges head‑on.