When the temperature drops, industries that handle chemicals often face new challenges—not only from the cold itself, but from how cold affects materials, grip, durability, and safety. Choosing the right chemical-resistant gloves for industrial work during cooler months is more than swapping one pair for another. It’s about selecting gloves that remain protective, functional, and comfortable, even when winter conditions are working against you.

Why Cooler Temperatures Matter

Cold weather doesn’t just make hands uncomfortable—it changes how gloves behave. Some key effects:

-

Reduced flexibility: Many glove materials become stiffer in cold, making dexterity harder and tearing more likely.

-

Slower chemical reactions: Cold slows down some chemical processes, but exposure is still risky if protection fails.

-

Condensation & moisture: Cold surfaces lead to condensation; gloves can trap moisture, making both hands and gloves colder and risking skin irritation or reduced barrier protection.

-

Slip hazards: Cold + wet = slippery. Hands working with tools or handling chemical containers need reliable grip, even when surfaces are slick.

These added demands mean that selecting chemical-resistant gloves for industrial work in cooler months must account for both chemical hazard and the effect of cold.

Key Features to Look For

Here are the features industrial users need to prioritize when selecting gloves for chemical handling in cold weather.

|

Feature |

Why It Matters in Cooler Months |

|

Material type (e.g., nitrile, neoprene, butyl rubber) |

Some materials stay flexible in cold; nitrile tends to be a good all-round choice because of its chemical resistance and puncture strength. |

|

Thickness / mil rating |

Thicker gloves offer better protection but reduce dexterity; cold already reduces dexterity, so there is a trade-off. |

|

Grip / texture |

Textured surfaces (fingertips, palm) help in wet or icy conditions. |

|

Cuff design |

Longer cuffs protect more skin, prevent roll back, and help seal out cold air or drips. |

|

Powder-free & latex-free formulation |

To avoid irritation, especially as skin is more vulnerable in cold, dry air. Also prevents issues where powder might trap moisture. |

Best Types of Gloves for Cold Chemical Exposure

Some glove lines from Atlantic Safety Products are designed to meet many of these criteria:

-

Black Lightning® Industrial Gloves – Heavy-duty black nitrile gloves offering chemical-resistant, industrial-hazard performance.

-

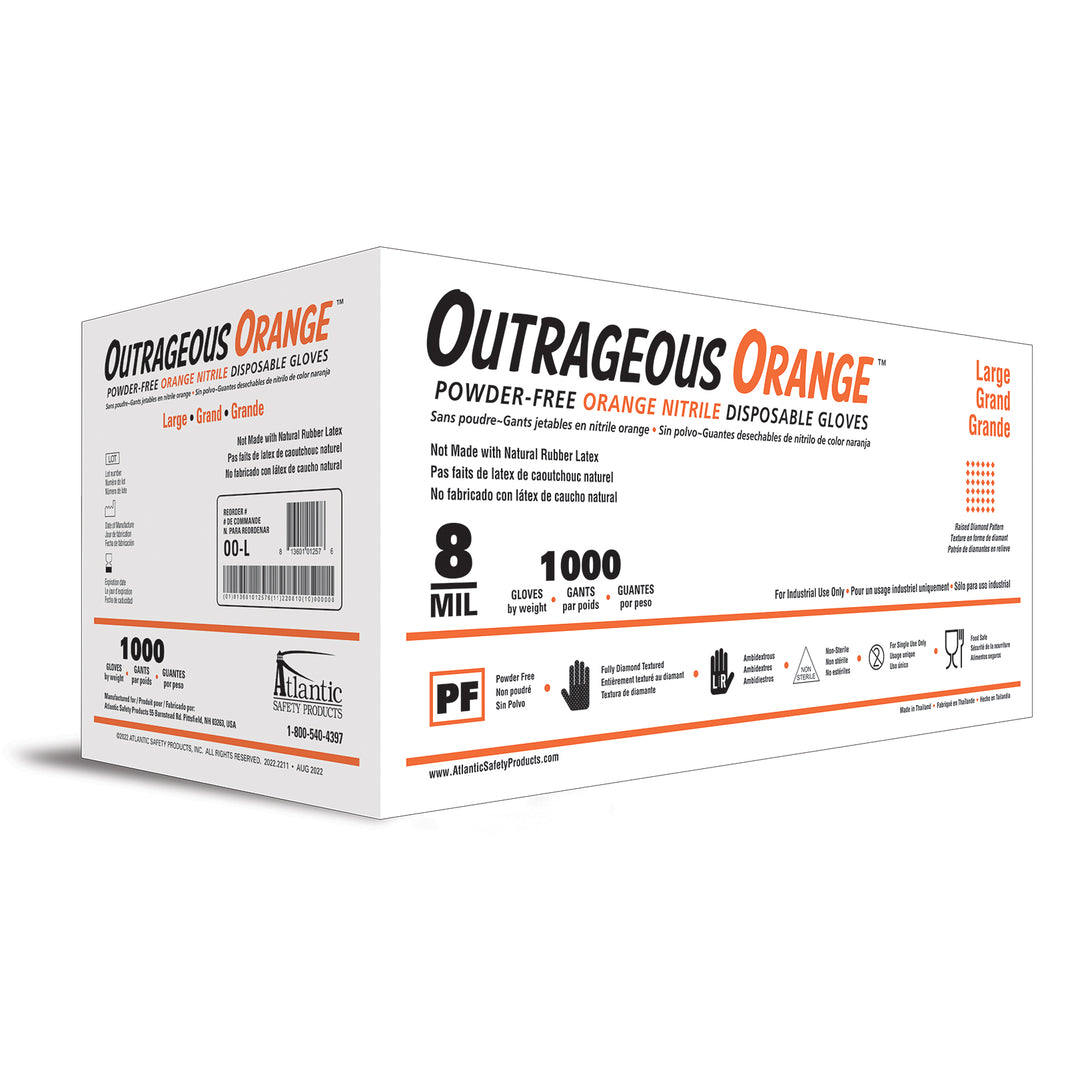

Outrageous Orange Industrial Gloves – 8 mil thickness, raised diamond grip, beaded cuff. These are designed to resist wear, maintain grip under wet conditions, and handle longer use.

-

InTouch Industrial Black Nitrile Gloves – Provide strong protection and stretch, good for day-to-day hazards where cold and chemical safety both matter.

Matching Glove Choice to Task

Depending on what chemical exposure is involved, colder conditions, and how frequently gloves must be changed, you’ll adjust what glove works best.

-

Handling concentrated acids or bases: Go with thicker gloves (6-8 mil or more) using nitrile or specialized materials. Look for “chemical resistance chart” data. The Black Lightning® line supplies this data.

-

Splashes, intermittent contact, cleaning: You might accept gloves of medium thickness, but ensure good grip and full coverage (long cuffs).

-

Work involving precision tools, small parts: Balance protection vs dexterity—so somewhat thinner gloves, but with textured grip. Cold will already reduce sensitivity, so the glove must still allow enough feel.

-

Outdoor or semi-outdoor chemical work: The gloves need to protect against cold wind, moisture, and possible freezing splashes. Insulated undergloves or layering can help, but the outer glove must remain tightly sealed and grip well when wet.

Maintenance & Use Tips for Cold Months

Selecting the right glove is only part of the solution. Proper use and maintenance help ensure they perform when needed.

-

Store gloves in a warm place before use, so they don’t stiffen immediately on exposure.

-

Inspect regularly for cracks, brittleness, or small tears—cold makes defects worse.

-

Dry hands well before slipping gloves on; moisture inside reduces thermal comfort and may degrade gloves faster.

-

Clean gloves properly when required—many chemical-resistant gloves will tolerate certain cleaning agents but you must follow manufacturer guidance.

-

Rotate gloves / replace when signs of chemical breakthrough or physical wear: thinning, loss of grip, visible damage.

Why Nitrile Is Often the Go-To

Nitrile gloves combine many advantages that suit cold and chemical exposure:

-

Excellent resistance to oils, solvents, and many industrial chemicals.

-

Better puncture and tear strength than latex or vinyl, especially when cold.

-

Latex-free, so reduced risk of allergic reactions in cold, dry skin.

-

Flexible enough when properly manufactured and in good condition, especially if stored and handled correctly.

-

Many nitrile gloves offer textured grip, longer cuffs, and enhancements (like diamond pattern) that help in wet or cold environments. For example, the Outrageous Orange Industrial gloves include a raised diamond pattern for superior grip in wet conditions.

Choosing From Atlantic Safety Products’ Offerings

Here are some recommendations from Atlantic Safety Products that align with the needs of chemical handling in cooler months:

-

Black Lightning® Industrial Gloves — opt for the heavier mil rating versions when working with harsher chemicals or longer exposure.

-

Outrageous Orange Industrial Gloves — for high visibility, better grip, and thicker material when conditions are cold and wet.

-

InTouch Industrial Black Nitrile Gloves — for more general tasks, when dexterity is more needed, but chemical resistance still matters.

You can also review the Industrial-Grade Heavy-Duty Nitrile Gloves page for a direct comparison of options designed for severe conditions.

Checklist: What to Ask Before You Buy

To make sure the gloves you choose really meet your needs in winter:

-

What chemicals will I be exposed to, and for how long? Check compatibility charts.

-

What is the minimum temperature I’ll be working in? Cold may require gloves with insulation, or use of layered gloves.

-

Is dexterity or grip critical for the job? Leather or thick gloves may protect, but may slow down work or reduce precision.

-

Are glove changes frequent enough? If gloves get wet or damaged, changing them is essential.

-

Do I have proper storage and maintenance? Gloves stored in very cold places stiffen; cleaning procedures must be followed.

Conclusion

When handling chemicals in cooler months, selecting chemical-resistant gloves for industrial work isn’t optional—it’s essential. Cold makes many materials stiffer, reduces grip, and can worsen chemical interactions. By choosing nitrile gloves with appropriate thickness, specific chemical resistance, good grip, and solid cuffs—such as the Black Lightning®, Outrageous Orange, or InTouch Industrial nitrile gloves from Atlantic Safety Products—you can maintain safety, reduce risk, and ensure worker comfort and efficiency even in harsher conditions.

Protecting hands properly in cold weather means fewer accidents, less downtime, and better performance—all of which add up. Choose wisely, maintain well, and the right glove will be one of your strongest lines of defense.